It is usually used within manufacturing contexts to produce hand tools, power tools, stamping dies, axes, pickaxes, injection molding machinery and other kinds of heavy equipment. Read More…

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

The Steel Supply Company brings you alloy, carbon and stainless steel shafting and tubing. Our steel fabrication services include hard chrome plating, induction hardening, honing, grinding, and non-standard items in order to meet your specifications. Visit our website to see our product line of both bars and tubes. We are ISO 9001:2008 certified.

As product specialists, we can meet your stainless steel needs. We stock T304304- and T303-grade stainless steel, as well as other cold-finished carbon bars. Pennsylvania Steel provides cold finished bar, tool steel, aluminum, stainless steel, tube/pipe, hot rolled bar, sheet/plate, expanded metal & grating, copper, brass and bronze. Visit soon!

As a world-class source for steel products, King Steel Corporation supplies companies across North America with what they need to get the job done. For over 50 years, we have continued to invest a great amount of both time and capital into purchasing new equipment and streamlining our processes. We’ve worked diligently to develop and maintain a reputation in our industry that represents growth, ...

More Tool Steel Service Centers

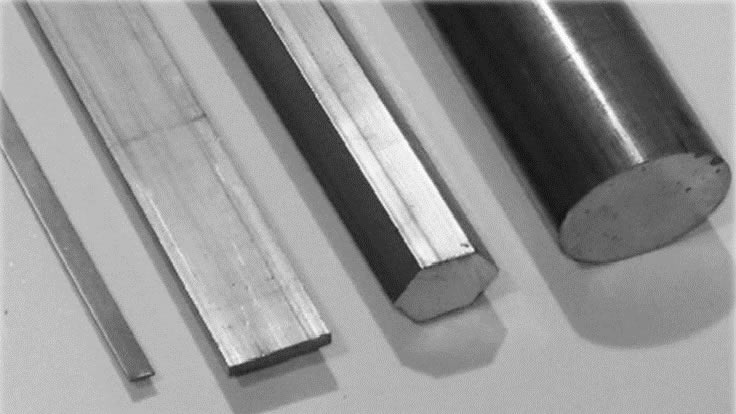

Tool steel is often used to build equipment that machines and cuts other types of metal. It is used in metal drawing, blanking, stamping, slitting, forming and embossing operations because of its hardness relative to the metal that it processes.

The American Iron and Steel Institute assigns tool steel grades that are used to determine tool steel's use. A tool steel's grade also identifies special characteristics of a given tool steel variety; such characteristics include chemical composition and reactivity. There are 11 tool steel grades, each of which is represented by a letter.

Grade A tool steel, for example, is used for cold working processes, while grade P tool steel is used for plastic molding. Every tool steel grade is characterized by high strength and moderate to high carbon content. In order to gain the desired hardness for metal processing, tool steel is carefully created during a precise alloying process.

Tool steel is produced in annealed condition, which means it is heated and formed into a desired shape and post-processed, which hardens the steel. There are many methods of producing tool steel. One common method is air hardening, in which case the steel, after annealing, is cooled and hardened by air.

Another very common hardening method is oil hardening, in which the steel is dipped in oil for hardening purposes. Water hardening is also common and involves dipping the hot steel into hot water, which causes the steel to become cool. There are three general classes of steel, each of which indicates appropriate applications and temperature resistance. The first is called cold work steel, which is used in environments with lower operating temperatures.

Hot work steel is exactly the same as cold work, but is used in operations when the metal becomes red-hot and pliable. Finally, high speed steel is able to maintain its properties in operating areas of more than 1,000°F. High speed steel is so named because it is used in drill bits and saw blades that are used to cut at very fast speeds; it can operate under these conditions because of its temperature resistance.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services