High Strength Steel

Every steel variety’s properties depend on the ratio of iron to alloying materials, usually carbon, as well as other additives. Also, a steel’s physical properties can be changed by metal treatment processes like hot and cold rolling. Read More…

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

The Steel Supply Company brings you alloy, carbon and stainless steel shafting and tubing. Our steel fabrication services include hard chrome plating, induction hardening, honing, grinding, and non-standard items in order to meet your specifications. Visit our website to see our product line of both bars and tubes. We are ISO 9001:2008 certified.

As product specialists, we can meet your stainless steel needs. We stock T304304- and T303-grade stainless steel, as well as other cold-finished carbon bars. Pennsylvania Steel provides cold finished bar, tool steel, aluminum, stainless steel, tube/pipe, hot rolled bar, sheet/plate, expanded metal & grating, copper, brass and bronze. Visit soon!

As a world-class source for steel products, King Steel Corporation supplies companies across North America with what they need to get the job done. For over 50 years, we have continued to invest a great amount of both time and capital into purchasing new equipment and streamlining our processes. We’ve worked diligently to develop and maintain a reputation in our industry that represents growth, ...

More High Strength Steel Service Centers

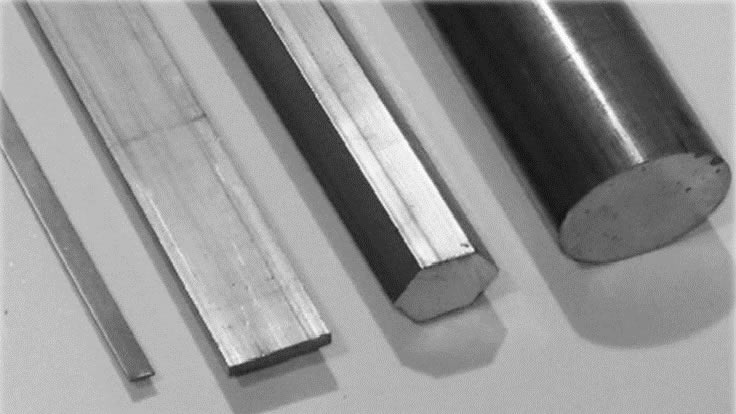

High strength steels usually feature a comparatively low carbon content, typically between 0.05 and 0.25% of the steel's mass, which allows the steel to retain qualities of weldability and formability. A long list of other elements are added to alter the properties of high strength steel; this list includes manganese, in some cases amounting to as much as 2% of the steel's mass.

Small quantities of other elements like copper, nitrogen, nickel, chromium and even some rare earth elements may also be added to give the steel a certain quality. High strength steel is known for its high structural integrity. This steel is often used in the automotive manufacturing and transportation industries to produce parts used in the construction of cars, trains, subway cars and heavy machinery.

When high strength steel is produced with the newest manufacturing techniques, it offers reduced weight, enhanced crash performance, manufacturing process consolidation and a reduction in costs.

A combination of cold rolling and proper alloying techniques produces high strength steel. Cold rolling, which is a metal working process in which metals are forced between rollers at or near room temperature, imparts higher qualities of strength because of the compressive stress to which the process subjects metals. Before a metal can be processed, it must first be alloyed.

High strength steels are usually alloyed with elements like copper, vanadium and titanium for strengthening. Advanced and ultra high strength steels have been developed over the past two decades in the steel industry and are stronger and less heavy than ever before. But with increased hardness and tensile strength comes a common problem: tooling materials that are not sturdy enough to handle the steel cab become damaged if exposed to it.

Improperly equipped machinery can become chipped and cracked if used to process metals that are too strong. For this reason, every metalworking process should be carefully planned based on variables of metal composition and equipment capacity; this reduces the likelihood of equipment failure, product loss and even worker injury.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services