The term “spring steel” describes a class of low alloy, medium-to-high carbon steel products with outstanding yield strength. Yield strength is the ability of a material to withstand severe bending and return to its original shape without deforming. Silicone is often present in spring steel stock alloys. These alloys are hardened, and cold rolled to increase yield strength. Spring steel is often cold drawn as wire or punched from flat stock to produce the final product. Saw blades, tape measures, helical springs, and car suspension parts are typical applications. Read More…

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

The Steel Supply Company brings you alloy, carbon and stainless steel shafting and tubing. Our steel fabrication services include hard chrome plating, induction hardening, honing, grinding, and non-standard items in order to meet your specifications. Visit our website to see our product line of both bars and tubes. We are ISO 9001:2008 certified.

As product specialists, we can meet your stainless steel needs. We stock T304304- and T303-grade stainless steel, as well as other cold-finished carbon bars. Pennsylvania Steel provides cold finished bar, tool steel, aluminum, stainless steel, tube/pipe, hot rolled bar, sheet/plate, expanded metal & grating, copper, brass and bronze. Visit soon!

As a world-class source for steel products, King Steel Corporation supplies companies across North America with what they need to get the job done. For over 50 years, we have continued to invest a great amount of both time and capital into purchasing new equipment and streamlining our processes. We’ve worked diligently to develop and maintain a reputation in our industry that represents growth, ...

More Spring Steel Service Centers

The special property of spring steel alloys is their ability to sustain strong twisting or bending forces without distorting. These steel alloys allow for continuous bending, compression, extension, and twisting. Spring steel alloys have a medium-to-high carbon content. Manganese and silicone are frequently used as additional alloy additives, with silicone as the foundation for high-yield strengths.

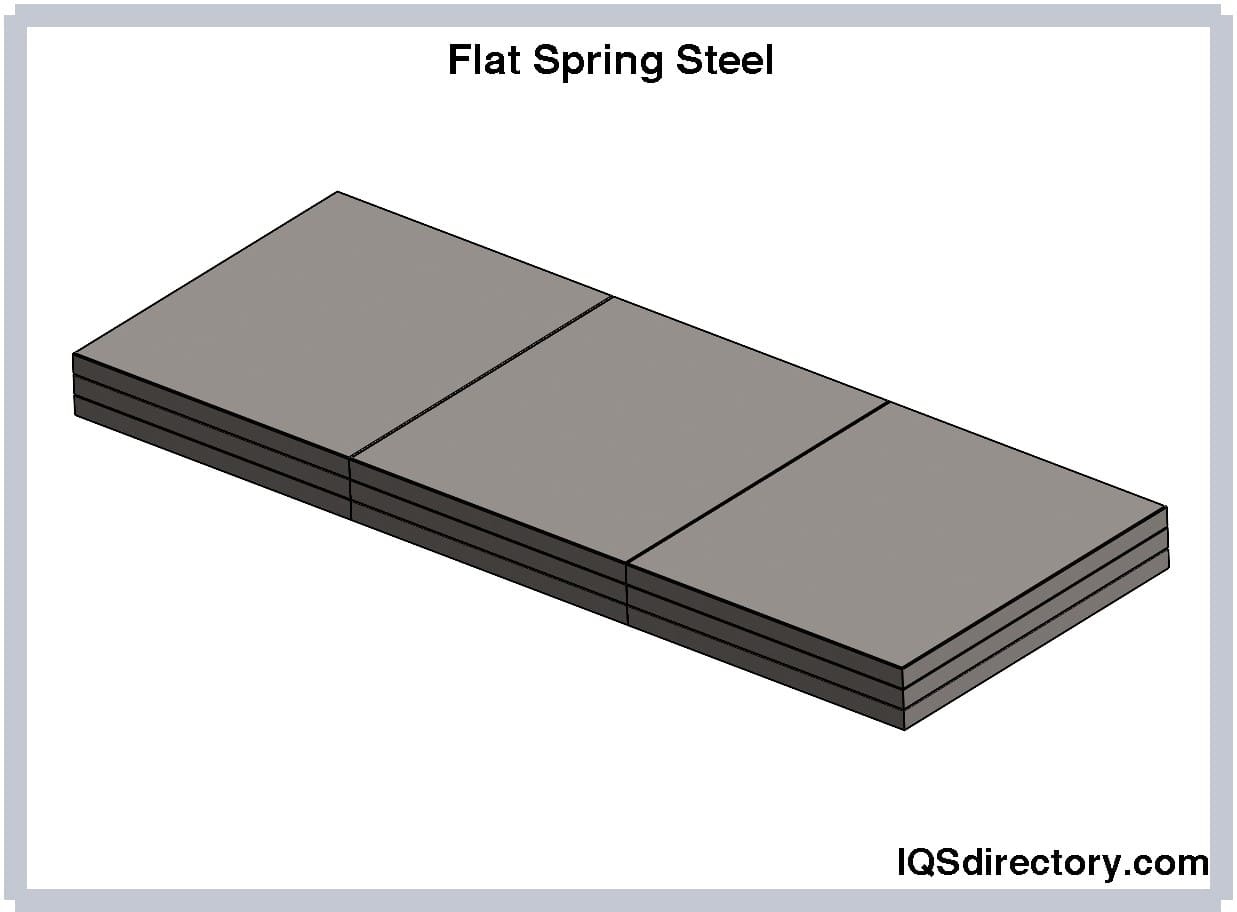

Since heating spring steel after manufacture could harm the alloy's resilience, the alloy stock is operated cold after casting to preserve and enhance yield strength. Spring steel components normally can’t be welded unless they are retempered later. Instead, the alloys are typically hardened to Rockwell C values between 42 and 60, then cold drawn or rolled into flat sheets or wire stock. After that, products are coiled with wire or punched from flat plates. Often, intricate pieces are created from soft, annealed stock and only hardened after they are finished.

Applications of Spring Steel

The silicon added to spring steel during the alloying process gives it the strength to withstand impacts and asymmetrical bending. Silicon enables the metal to stretch and bend without sustaining permanent damage. Spring steel is an excellent raw material for manufacturers requiring sturdy, heat- and abrasion-resistant metal. Different types of spring steel have varying degrees of flexibility and hardness. For instance, machine components, gun parts, knives, small files, mechanical springs, clips, and anything else needing the characteristics of high carbon are all made from cold-rolled, annealed spring steel.

However, blue-tempered steel is more reasonably priced and is often used to make blades for healthcare facilities, flat springs, motor springs, steel tapes, valves, and reeds. Spring steel is a common material used to make molds for plastic injection molding. Certain types of music wire, such as piano and guitar strings, can also be made from spring steel.

Manufacturing Process

Steel service providers use a wide range of steel working techniques to give steel various properties. The properties that make the various spring steel kinds usable depend on a particular steelworking technique. For instance, when heating tempered spring steel, flexibility and impact resistance aren't sacrificed to increase hardness. Steel that has been annealed is heated until it becomes malleable, but the temperature is always kept below the steel's recrystallization temperature. To enhance the metal's performance at high temperatures, heat-treated spring steels may include additions like cobalt and nickel.

Spring steel might undergo other production procedures to improve its qualities, including quenching in water or oil and following heat treatments to cool and harden the steel. Another post-heat-treatment hardening technique is air hardening, which can be more cost-effective and equally effective than quenching techniques. Slitting, edging, leveling, and other physical shaping techniques can modify the shape of spring steel to meet standards.

Advantages of Spring Steel

The most distinguishing quality of spring steel is its simplicity in coiling into a helix shape, which enables it to store energy when compressed and release it when expanded. In this respect, elastic materials with good strength might be characterized as spring steels.

Additionally, spring steel has a low hardness to bend without breaking or fracturing and great fatigue resistance. Its ability to bend or twist repeatedly over time makes it suitable for applications like door hinges, drawer slides, conveyor belts, and other machinery parts. Since spring steels have these characteristics, they have been used for ages.

Other Applications of Spring Steel

Since Spring Steel is an alloy recognized for its exceptional strength and elasticity, this makes it the ideal substance for several uses, such as:

- Producing springs

- Making automotive components like suspension systems

- Constructing tools and machinery

- Producing surgical equipment

- Knife Production

Choosing the Correct Spring Steel Supplier

To make sure you have the most positive outcome when purchasing spring steel from a spring steel supplier, it is important to compare at least 4 companies using our spring steel directory. Each spring steel supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each spring steel business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple spring steel companies with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services