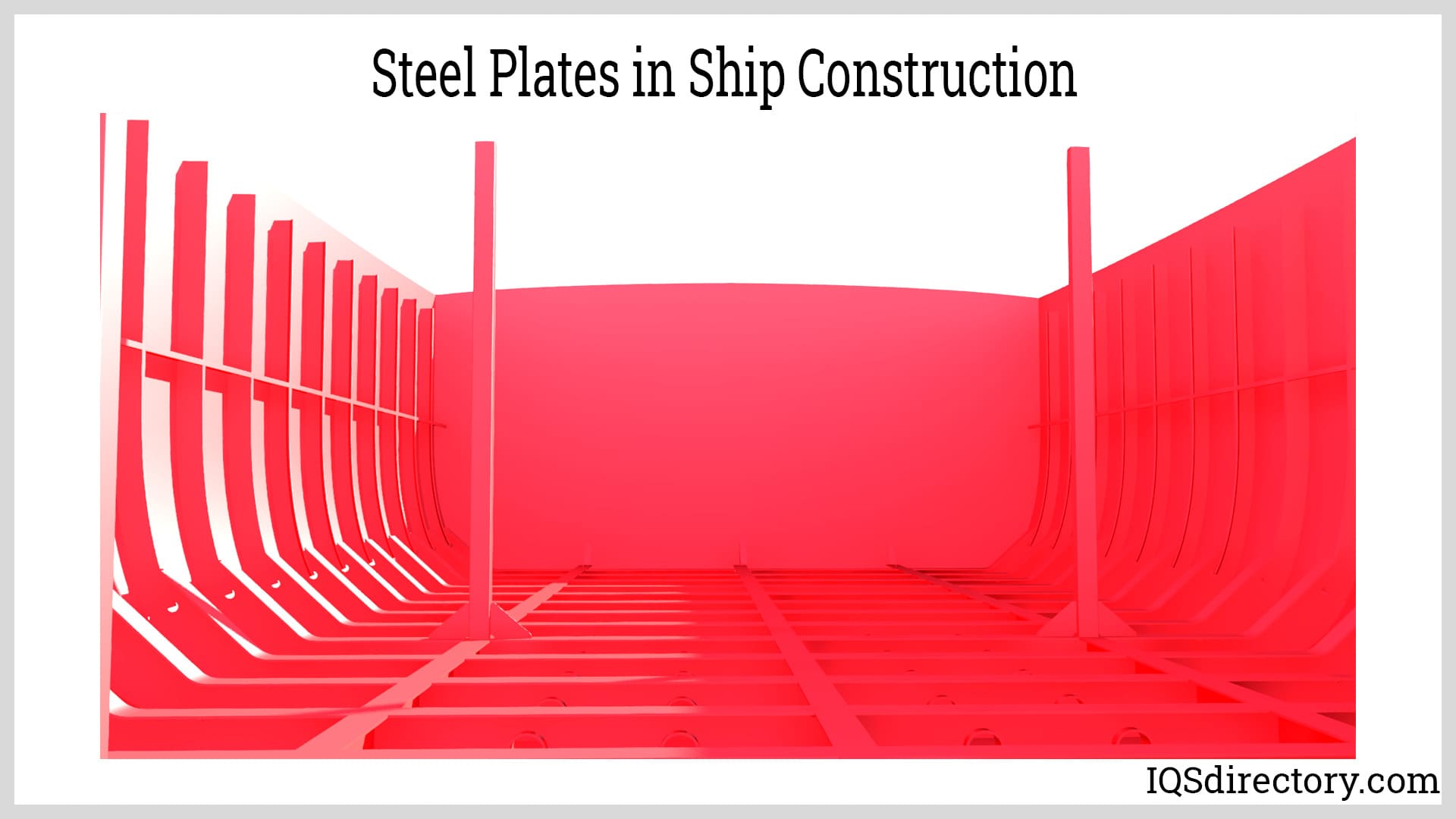

Metal goods are frequently made using steel plates. Steel plate is manufactured in various thicknesses and widths, then cut and welded together to form the finished item. There are various kinds of plates, including high-carbon and stainless steel plates. Some kinds of plate steel are used to make structures, while others make both commonplace objects like wood furnaces and less commonplace items like ship hulls. Flat steel is a common name for a steel plate. Read More…

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

The Steel Supply Company brings you alloy, carbon and stainless steel shafting and tubing. Our steel fabrication services include hard chrome plating, induction hardening, honing, grinding, and non-standard items in order to meet your specifications. Visit our website to see our product line of both bars and tubes. We are ISO 9001:2008 certified.

As product specialists, we can meet your stainless steel needs. We stock T304304- and T303-grade stainless steel, as well as other cold-finished carbon bars. Pennsylvania Steel provides cold finished bar, tool steel, aluminum, stainless steel, tube/pipe, hot rolled bar, sheet/plate, expanded metal & grating, copper, brass and bronze. Visit soon!

As a world-class source for steel products, King Steel Corporation supplies companies across North America with what they need to get the job done. For over 50 years, we have continued to invest a great amount of both time and capital into purchasing new equipment and streamlining our processes. We’ve worked diligently to develop and maintain a reputation in our industry that represents growth, ...

More Steel Plate Service Centers

There are several techniques to shape steel plates the most popular being hot rolling. Hot rolling occurs above the steel’s recrystallization temperature. Recrystallization is when a material's structure changes to the point where it loses rigidity and becomes ductile. In other words, steel can become easily formable when sufficiently heated. After recrystallization, the steel is compressed into a flat shape under a succession of rollers. This procedure provides the steel with shape, strength, and longevity.

It is also possible to cold roll steel plates, which is very similar to hot rolling except that no heat is applied to the steel during the cold rolling process. As a result, the possibility of oxidation decreases, and the material receives compressive stress, strengthening it. However, hot rolling causes fewer deformational stresses in the material compared to cold rolling. Other plate-forming services include milling, deburring, straightening, shot or sand blasting, heat treating, stress relieving, annealing, normalizing flame cutting, and special testing. In steel service facilities, pickling, a process that uses sulfuric or hydrochloric acid to clean or remove impurities from steel, is frequently employed on steel plates.

Types of Steel Plates

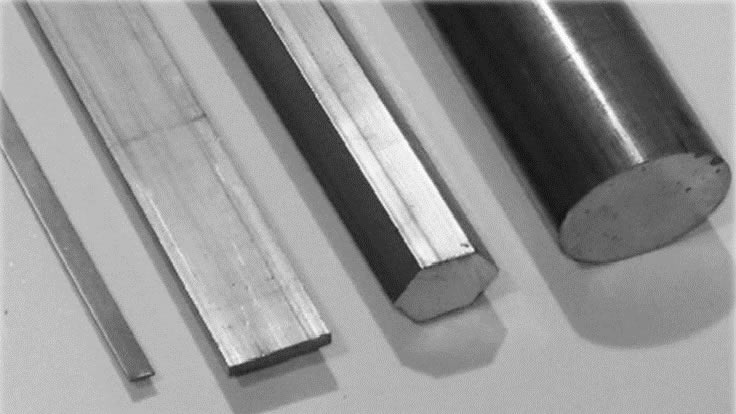

Steel plate comes in various varieties, including stainless steel (also known as Stainless Steel 304), high-carbon, low-carbon, and alloy steel plates. These steel plates have various purposes; some are domestic goods, while others are much larger, such as buildings or tanks. Standard grade steel used in structural plates is used for reinforcing plates and building girders.

A flat steel plate is fastened to a concrete foundation using anchor bolts, frequently done to secure steel beams. The steel beam is bolted or welded to the plate to establish a firm base upon which to build. The width of the plate is used to distribute the building's load.

Low-carbon steel is often used for structural-grade plates. This steel is easy to drill and shape to meet construction needs. A36 grade steel is the used for a structural steel plate. This plate steel type is used to construct heavy machinery like bulldozer chassis and earth mover booms. Other specialist plate steel grades exist, such as marine, armor, and bullet-proof grades.

Applications of Steel Plates

Construction Applications

Steel plates have several uses in the building sector. They are particularly prevalent while building warehouses, buildings, and bridges. Large commercial structures like stadiums and airports are also built using steel plates. In addition, bridges and building foundations can benefit from steel plates.

Military Applications

Steel plates are often used to fortify military structures and vehicles. They are frequently seen in military vehicles such as jeeps, tanks, trucks, helicopters, planes, and ships. They are also employed when testing ammunition and weaponry. Steel plates are used in some capacity by every component of the armed forces.

Automotive Applications

Many cars today contain steel plates on their chassis. They are vital to keeping drivers and passengers safe in the case of crashes because of their strength. In addition to being reasonably strong, steel plates can also be lightweight, helping cars run more efficiently.

Advantages of Steel Plates

Steel plates resist rust and wear. They are made in a far wider range of thicknesses than normal sheet steel. A steel plate is ideal in applications requiring an extremely strong construction.

Steel plates can bear tremendous strain from the worst environmental factors. Although steel plates are mainly used for bracing and reinforcing, it has been demonstrated that plate steel possesses a high degree of flexibility.

Choosing the Proper Steel Plate Manufacturer

To make sure you have the most positive outcome when purchasing steel plates from a steel plate manufacturer, it is important to compare at least 5 companies using our list of steel plate manufacturers. Each steel plate manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each steel plate company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple steel plate companies with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services